We are taking up the challenges of digital transformation and Industry 4.0 and develop innovative solutions that boost your business. Benefiting from state-of-the-art development methods, our software solutions for predictive asset health, product quality, production planning and energy management contribute in actively saving money, increase profitability and conserve resources.

Use our digital technologies to turn data into information and information into value.

The digital future has already begun.

Service categories

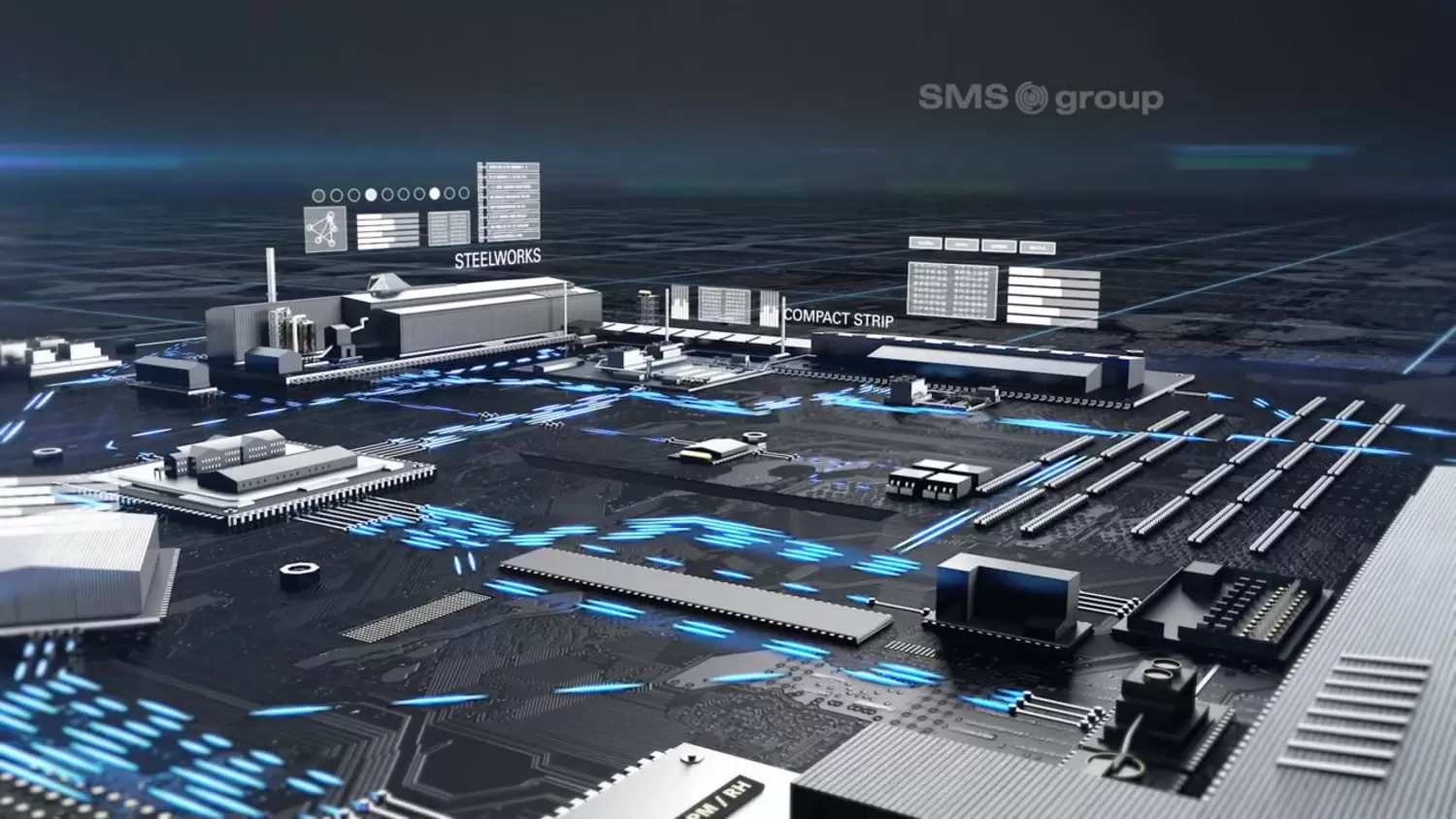

The first learning steel plant

Our vision comes true

Big River Steel produces pipe grades for pipelines, silicon steels for electrical steel and AHSS grades for the automotive industry on SMS group equipment. As systems supplier for the steel mill complex, SMS group supplied all the equipment, process know-how and automation technology and supported BRS during commissioning.

From the combination with SMS digital's innovative solutions for data infrastructure, digital products and machine learning resulted in the world's first learning steel mill.

Services for digitalization

Sorry, there are no results for the search term.